Summer brings with it great weather for roofing, but also high temperatures and fluctuating humidity. Awareness of the impact of this is key to ensuring systems are installed correctly, and products work effectively.

With that in mind, we thought this would be a good time to remind everyone of the hot weather's effect on liquid waterproofing products, and best practices for application and storage.

The advice offered here generally applies equally, whether you are involved in new build, maintenance or refurbishment.

Liquid applied membranes and adhesives

Liquid applied systems have become very popular, because they are quick and easy to work with, yet are versatile, durable and long-lasting.

Cold applied liquid waterproofing systems are multi-layer solutions with a single component liquid used per layer. The liquids are generally polymethyl methacrylate (PMMA) or polyurethane (PU) based. PMMA is a two-part product that requires a catalyst for the curing process, whereas PU cures by reacting with moisture in the air.

Once the curing process is complete, you are left with sturdy, seamless waterproofing that can now tolerate extreme temperatures, and is flexible, meaning it will compensate for shrinkage or expansion due to changes in temperature, as well as building movement.

Note that any roofing system secured with PU adhesive rather than mechanical fixings (or ballast) is subject to the issues discussed here. If you are installing one of our single ply systems using adhesive, then this advice will also apply to you.

How temperature and humidity affect polyurethane liquids

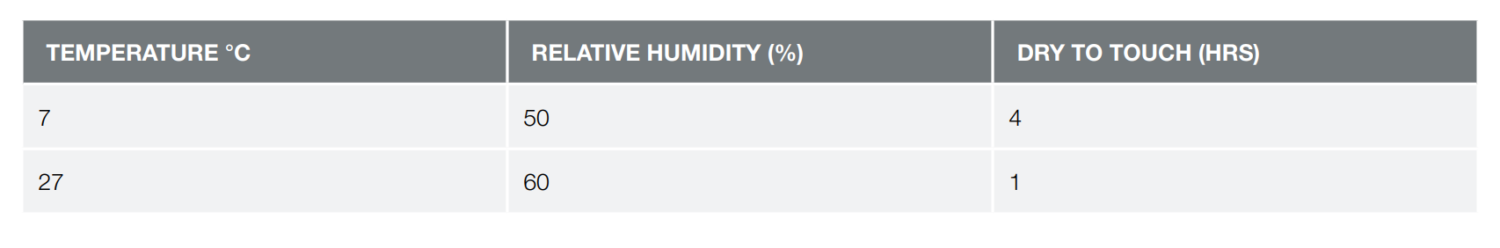

Polyurethane products tend to become thinner in warmer temperatures, which should increase your coverage rates. Curing is also much

faster when the ambient temperature increases. Here is a detail from one of our datasheets (Starcoat QC).

You can download these datasheets at the bottom of each product page on our website – or you can find all of them, as well as other guidance, brochures and more, availabhere: Axter downloads

Self-adhesive membranes may become tacky quicker in high temperatures, so installers need to take more care as they lay them onto the structural support deck.

Humidity means moisture, of course, so high humidity also causes the curing reaction for PU moisture-triggered products to increase, with longer curing times experienced as humidity falls.

When polyurethane products get too hot or humidity is too high, they may become more quick-reacting, and it can be necessary to adapt your installation technique to complement the conditions you are working within. If curing is happening at a faster rate, for example, it could be a good idea to install your cold-applied liquid system by laying down liquid over shorter sections of the roof, so that you can go back to complete work on that run before it loses its tack.

The importance of technical datasheets

Always check the product datasheet before any work starts, to make sure this is the product specified for your job, and again during your prep, to ensure conditions are appropriate and also that you have the right equipment for measuring all relevant materials. Datasheets will advise you to check ambient temperature, substrate temperature, humidity and perhaps other factors. Again, dew point is more a winter issue but in principle it must always be borne in mind. A lost day because temperature is too high is always preferable to having to repeat installation or replace damaged materials.

The documents also contain other vital information. For example, the size and spacing of adhesive beads necessary for forming a strong bond might vary from one product to another.

The same temperature limits generally apply to transport, storage and installation. In general, avoid leaving products in direct, hot, sunlight, and never leave them on a very hot (or very cold) surface. Store products in dry locations and moderate temperatures. Take out of controlled storage only what you will use directly.

Other summer roofing tips

- If installing RBM roofing during warm weather, adopt the technique of roll bars and pulling the membranes towards you in a traditional manner; the approach of rolling it away as you stand on it can leave footprints damaging the aesthetic of the product finish.

- Maintenance for most roof types, including green roofs, is key all year round and should be undertaken bi-annually, and doesn’t vary much in summer; if you have on-roof irrigation on your green roof you may well want to think about adding this as warmer weather will dry out any vegetation, however, you might want to check on it more in hot weather.

You can always ask Axter

If you have doubts about any issue, you can always check in with us. Our team is ready to help on any matter, and will answer any question promptly and knowledgeably.

Read our tips for winter here.

Get in touch on 01473 724056 or via [email protected].